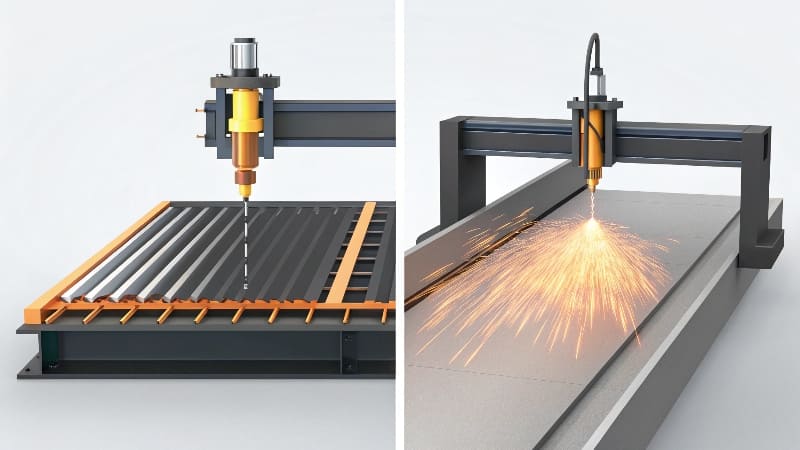

Choosing the right cutting method is tough and a costly mistake. Pick the wrong one, and you face poor quality, slow production, and wasted money. Understanding their differences makes it clear.

Plasma cutting1 is the cost-effective choice for thick, conductive metals, offering great power for a lower investment. Laser cutting2 provides superior speed and precision on thinner materials with an exceptionally clean edge, but at a significantly higher initial cost.

But the choice is not just about the initial price tag and the thickness of the metal. The real difference is in the performance, the finished product, and what it takes to operate each machine on a daily basis. The "best" tool always depends on the job you need to do. So, let’s get into the details to figure out which is the right one for your workshop.

Is a laser cutter really better than a plasma cutter?

Everyone talks about laser cutting’s precision, making you wonder if plasma is outdated. You might be overspending on laser technology for jobs where plasma excels and saves you money.

No, a laser cutter is not always better. For cutting thick conductive metals3 over one inch, plasma is often more effective and much more economical. Laser cutting is superior for high-precision work and speed on thinner materials, both metal and non-metal alike.

I see this question come up a lot. People hear "laser" and immediately think it's the best technology available for everything. One of our senior technicians told me about a client who was ready to spend a fortune on a high-power laser system to cut two-inch-thick steel plates for heavy equipment manufacturing4. We showed him how a modern high-definition plasma system5 could do the job for a fraction of the initial investment and with very reasonable operating costs6. The laser would have been overkill and financially inefficient for his specific work. The "better" tool is the one that profitably and efficiently does the job you need it to do.

Initial Investment and Operating Costs

Your budget is the first place to start. A plasma cutting system is significantly less expensive to buy than a laser cutter. The consumables, like electrodes and nozzles, are also more affordable. For many small to medium-sized shops, this makes plasma the only practical choice to get started.

Precision and Cut Quality

This is where the laser shines. A laser produces a very narrow kerf (the width of the material removed by the cut) and a smooth, clean edge that often requires no secondary finishing7. Plasma cuts have a wider kerf and can leave behind dross (re-solidified metal) that needs to be cleaned off.

| Feature | Plasma Cutter | Laser Cutter |

|---|---|---|

| Initial Cost | Low to Medium | High to Very High |

| Operating Cost | Low | Medium to High |

| Precision | Good | Exceptional |

| Best For | Cost-effective cutting | High-precision jobs |

How do they stack up on speed and thickness8?

Your production line has a bottleneck. You need to make cuts faster without losing the quality your customers expect. Choosing the slower method for your material can kill shop efficiency.

Laser cutting is generally much faster than plasma on materials up to about half an inch thick. For thicker metals, plasma cutting's raw power allows it to maintain or even exceed the laser's speed, making it the better choice for heavy fabrication.

The physics behind each process explains this difference. Plasma cutting uses a high-velocity jet of ionized gas (plasma) to melt the metal and blow it away. It’s a brute-force thermal process. Laser cutting uses a highly focused beam of light to melt, burn, or vaporize the material in a very small area. For thinner sheets, the laser's focused energy is incredibly efficient and quick. But as the material gets thicker, that light beam struggles to penetrate all the way through efficiently. This is where plasma's powerful arc takes over. It can simply melt more metal, faster, once you get into heavy plate territory.

The Speed Advantage: Where Laser Shines

On thin sheet metal, nothing beats a laser. For applications like manufacturing HVAC components, automotive panels, or intricate metal signs9 from materials less than a quarter-inch thick, a laser cutter will get the job done faster and more cleanly every time.

The Power for Thickness: Plasma's Domain

Once you need to cut metal plates that are an inch thick, or even several inches thick, plasma is the clear winner. A laser powerful enough to cut very thick metal is incredibly expensive and slow. Plasma offers unmatched capability for cutting thick, electrically conductive metals.

| Material Thickness | Faster Method | Main Reason |

|---|---|---|

| Under 1/2" (12mm) | Laser | Focused energy, rapid vaporization |

| Over 1" (25mm) | Plasma | High-energy arc penetrates deep |

Plasma cutting looks like a great, affordable option for your shop. But are you prepared for the operational realities, like the fumes, the noise, and the necessary cleanup work afterward?

The main disadvantages are a wider cut kerf, the creation of a significant heat-affected zone (HAZ)10, and the production of hazardous fumes11, loud noise, and dross. It often requires secondary finishing7 to get a smooth, clean edge.

The founder of ARCTHERM always stressed that a cheap cut becomes expensive if it compromises safety or requires hours of extra labor. This is so true for plasma cutting. While the machine is affordable, you must factor in the costs of a proper downdraft table or water table to control sparks and fumes. You also need to budget for the time your team will spend grinding or chipping away dross to get a finished part. Laser cutting is a much cleaner process, with fewer fumes (though ventilation is still essential) and almost no post-cut cleanup. Don't forget that plasma cutting is also very loud and produces intense UV light, so personal protective equipment (PPE)12 is non-negotiable for the operator.

Workplace Environment and Safety

Plasma cutting generates a lot of smoke and noxious fumes that must be managed with a good ventilation system. The process is also very bright and loud. In contrast, laser cutters are often enclosed, which helps manage fumes and significantly reduces noise.

Cut Quality and Post-Processing

The heat from a plasma torch affects a larger area of the metal, creating a "heat-affected zone" or HAZ. This can change the properties of the metal near the cut. Plasma also leaves dross on the bottom edge of the cut, which must be removed manually.

| Disadvantage | Plasma Cutting Impact | Laser Cutting Comparison |

|---|---|---|

| Fumes & Noise | High levels, requires ventilation | Lower levels, often enclosed |

| Heat-Affected Zone | Larger, can affect metal | Minimal, very localized heat |

| Dross | Common, requires cleanup | Very little to none |

What should you absolutely not cut with a plasma cutter?

You have a new material to cut and your plasma cutter is ready to go. But trying to cut the wrong material can damage your machine, ruin consumables, and waste the workpiece.

You should not cut any non-conductive materials13 with a plasma cutter. This includes wood, plastic, glass, or composites. The process fundamentally requires an electrical circuit to be completed through the material being cut.

This is the most basic rule of plasma cutting, and forgetting it can be a costly mistake. I remember one of our sales guys telling me about a new client who was frustrated that his new plasma cutter wasn't working. After a few questions, he discovered the client was trying to cut a thick piece of composite paneling. He just assumed it could cut anything. We had to explain to him how the technology works. The plasma torch creates an electrical arc between the electrode in the torch and the workpiece itself. If the workpiece can't conduct electricity, the circuit can't be completed, and no cutting will happen. It’s a simple but critical piece of knowledge.

The Rule of Conductivity

The heart of plasma cutting is electricity. The process only works on materials that can conduct electricity, allowing the plasma arc to form and transfer its intense heat to the workpiece.

Other Problematic Setups

Even with conductive metals, you can run into trouble. Trying to cut stacked sheets of metal is a common mistake. The small air gap between the sheets can interrupt or weaken the electrical arc, leading to a poor or incomplete cut. Very rusty or heavily painted metal14 can also be a challenge because the surface coatings can act as an insulator, preventing a good electrical connection.

| Material Type | Can a Plasma Cutter Cut It? | Why? |

|---|---|---|

| Mild Steel, Stainless, Aluminum | Yes | Electrically conductive |

| Wood, Plywood, MDF | No | Not electrically conductive |

| Plastic, Acrylic | No | Not electrically conductive |

| Glass | No | Not electrically conductive |

Conclusion

Plasma cutting is great for thick, conductive metals on a budget. Laser is for high-precision, high-speed cutting of thinner materials. The right choice always depends on your specific job needs.

Explore the benefits of plasma cutting for thick metals and its cost-effectiveness. ↩

Learn about laser cutting's precision and speed advantages for thinner materials. ↩

Find out which metals are ideal for plasma cutting and their applications. ↩

Explore the applications of plasma cutting in the heavy equipment industry. ↩

Discover the advancements in plasma cutting technology with high-definition systems. ↩

Get insights into the ongoing costs associated with plasma cutting systems. ↩

Learn about the additional processes required for finishing plasma-cut edges. ↩

Learn how speed varies between plasma and laser cutting based on material thickness. ↩

Learn how laser cutting excels in creating detailed designs for metal signage. ↩

Understand the implications of HAZ on metal properties during plasma cutting. ↩

Explore the health and safety considerations related to fumes produced by plasma cutting. ↩

Find out the essential safety gear needed when operating plasma cutting equipment. ↩

Learn about the limitations of plasma cutting and materials to avoid. ↩

Learn about the difficulties of cutting coated metals with plasma technology. ↩