You see them in fabrication shop1s everywhere, but how plasma cutter2s work seems like complex science. This can make them intimidating, preventing you from using them to their full potential.

A plasma cutter2 works by sending an electric arc3 through a gas, like compressed air4, which is passed through a constricted opening. This superheats the gas into a state of matter called plasma, which melts the metal while a high-velocity jet blows away the molten material.

It sounds complicated, but the core idea is simple. Think of it like a tiny, focused bolt of lightning that's hot enough to melt metal instantly. A few years ago, this was the go-to technology for almost all metal cutting. Now, with laser cutters becoming more common for thin sheets, plasma has really solidified its role as the king of cutting thicker materials cost-effectively. Understanding how it operates is the first step to mastering this essential workshop tool.

What is the real point of a plasma cutter2?

With newer technologies available, you might wonder if plasma cutting is still relevant. You could be overlooking a powerful and affordable solution perfect for many common industrial cutting jobs.

A plasma cutter2's main purpose is to provide a fast, powerful, and highly cost-effective method for cutting any electrically conductive metal. It particularly excels at cutting thick plates5 that are too difficult or expensive for other methods like laser cutting6.

The real point is value. I often talk to shop owners who are trying to decide on their next big equipment purchase. Our founder always puts it this way: "Don't buy the fanciest tool, buy the tool that makes you the most money." For a huge range of jobs, that tool is a plasma cutter2. It hits the sweet spot between performance and cost. It’s significantly faster than oxy-fuel cutting on most materials and much cheaper to buy and run than a high-power laser system. Its ability to quickly slice through one, two, or even three-inch thick steel makes it indispensable for heavy fabrication, construction, and repair work.

The Workhorse of the Fabrication Shop

Plasma cutting is about getting the job done efficiently without a massive upfront investment. While lasers are taking over the thin-sheet market, plasma remains the undefeated champion in the realm of thicker, heavy-duty applications. It offers a balance that is hard to beat for small and large shops alike.

| Cutting Task | Plasma Cutter Advantage | Competing Method | Why Plasma is Often Better |

|---|---|---|---|

| Thick Plate Cutting (>0.5") | Speed & Cost | Oxy-fuel / Laser | Faster than oxy-fuel; much lower cost than laser. |

| Cutting Stainless & Aluminum | Versatility | Oxy-fuel | Oxy-fuel cannot cut stainless steel or aluminum. |

| General Fabrication & Repair | Affordability | Laser | Much lower initial investment and operating costs. |

What gas do you actually use for plasma cutting?

Choosing the wrong gas for your plasma cutter2 is a common and costly mistake. It can lead to bad cut quality7, rapid consumable wear, and a lot of frustration.

Compressed air is the most common gas used for plasma cutting because it's cheap and readily available. For better quality on specific metals, specialty gases are used: oxygen for mild steel, nitrogen for stainless steel, and argon-hydrogen mixes8 for aluminum.

I had a great conversation about this with one of our senior technicians. He said, "Think of it like fuel for a car. You can use regular gas and the car will run fine. But if you have a high-performance engine, premium fuel will make it run cleaner and more powerfully." It's the same with plasma. Clean, dry compressed air4 is the "regular gas" – it’s a fantastic all-rounder. But if you are cutting a lot of mild steel, switching to an oxygen plasma gas will give you a much cleaner, squarer cut edge with less dross9. This can save you a huge amount of time on cleanup later. The small extra cost for the gas is often paid back by the savings in labor.

Matching the Gas to the Metal

The gas you choose has a direct impact on the cut quality7, cutting speed10, and the life of your consumables11 (like the electrode and nozzle). Making the right choice is critical for optimizing your cutting operations.

| Gas Type | Best For (Material) | Benefit | Potential Downside |

|---|---|---|---|

| Compressed Air | All-around (esp. mild steel) | Lowest cost, versatile | Good, but not the best quality |

| Oxygen | Mild Steel | Excellent cut quality7, minimal dross9 | Higher gas cost, faster consumable wear |

| Nitrogen | Stainless Steel, Aluminum | Good cut quality7, good consumable life | Higher gas cost than air |

| Argon/Hydrogen | Thick Stainless Steel, Aluminum | Excellent quality on thick non-ferrous | Highest gas cost |

What are the disadvantages of plasma cutting?

Plasma cutting seems like a perfect, low-cost solution for cutting metal. But if you ignore its downsides, you can face unexpected costs, safety hazards, and extra labor requirements.

The main disadvantages are a wider cut (kerf), a notable heat-affected zone12 (HAZ), and the creation of dross9 on the cut edge that requires cleanup. It also produces loud noise and hazardous fumes that demand proper safety measures13.

<sup id=](https://jescut.com/wp-content/uploads/2025/08/0810-4.jpg) 9 on the bottom edge of a plasma-cut part" title="Dross on a Plasma Cut Edge" />

9 on the bottom edge of a plasma-cut part" title="Dross on a Plasma Cut Edge" />

When I was first learning, I was amazed by the raw power of a plasma cutter2. I asked our founder what the catch was. He told me, "The power isn't free. You pay for it with heat, noise, and cleanup." That really stuck with me. The intense heat doesn't just cut the metal; it affects the area around the cut, creating a heat-affected zone12 that can make the steel brittle. The cut itself is also wider than a laser's, which might matter for very intricate parts. The biggest day-to-day issue is dross9, that slag of re-solidified metal on the bottom of the cut. Someone has to take the time to grind that off, which adds a labor cost to every part you make.

The Hidden Costs and Considerations

Understanding these drawbacks isn't meant to discourage you from using plasma. It's about being prepared. Factoring in the cost of a good ventilation system14 and the time for post-cut finishing gives you a true picture of the total operational cost.

- Cut Quality: The kerf is wider than a laser, and the HAZ can be an issue for parts that need to be welded or machined near the edge.

- Work Environment: The process is loud and produces intense UV light and fumes. Proper ventilation and personal protective equipment (PPE), including eye and hearing protection, are non-negotiable.

- Post-Processing: Dross removal is the most common follow-up task. While modern high-definition plasma systems have greatly reduced dross9, it's often still a factor to consider.

What should you not cut with a plasma cutter2?

You have a powerful plasma cutter2 and a new job, but using it on the wrong material is a rookie mistake. It will fail to cut and can even damage your equipment.

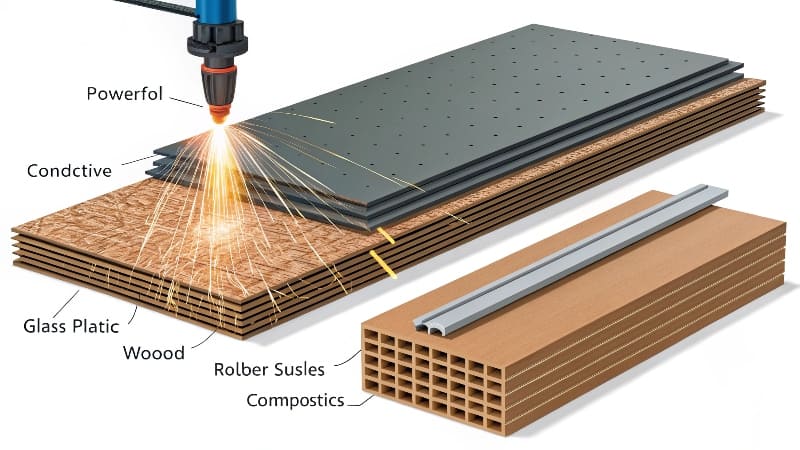

You must never try to cut non-conductive materials15 with a plasma cutter2. The list includes wood, plastic, glass, rubber, and composites. The entire process relies on the material's ability to conduct electricity.

This is the most fundamental rule of plasma cutting. I remember a customer calling our support line, completely confused about why his brand-new cutter couldn't even scratch a piece of thick plastic sheeting. We had to explain the science. A plasma cutter2 works by creating an electrical circuit that flows from the torch's electrode, through the superheated plasma arc, into the workpiece itself, and back to the power supply through the ground clamp. If the material you're trying to cut, like wood or glass, can't conduct electricity, that circuit remains open. The arc can't form, and no cutting will happen. It's a simple electrical principle that defines the machine's capability.

The Non-Negotiable Rule: Conductivity

Beyond non-conductive materials15, there are other setups that can cause problems, even with metal. Be cautious with these situations to ensure a clean, successful cut every time.

| Material / Situation | Can a Plasma Cutter Cut It? | Why It's a Problem |

|---|---|---|

| Wood, Plastic, Glass | No | These materials do not conduct electricity. |

| Stacked Metal Sheets | With Difficulty/No | The air gap between sheets can interrupt the electrical arc. |

| Heavily Rusted/Painted Metal | With Difficulty | Rust and thick paint act as insulators, preventing a good connection. |

| Concrete or Stone | No | Not electrically conductive. |

Conclusion

Plasma cutting brilliantly turns gas into a powerful tool for slicing through conductive metals. By understanding its process, gas needs, and limitations, you can use it safely and effectively.

Explore the significance of plasma cutting in various fabrication shop applications. ↩

Explore this resource to understand the fundamentals of plasma cutters and their applications in metal fabrication. ↩

Learn about the science behind electric arcs and their crucial role in plasma cutting technology. ↩

Discover why compressed air is the most common gas for plasma cutting and its benefits. ↩

Find out why plasma cutting is preferred for thick plate applications in fabrication. ↩

Learn the differences between plasma and laser cutting to choose the right method for your needs. ↩

Understanding cut quality is essential for achieving optimal results in plasma cutting. ↩

Discover the advantages of using argon-hydrogen mixes for cutting aluminum and stainless steel. ↩

Learn about dross formation and effective strategies for minimizing cleanup. ↩

Learn how to optimize cutting speed for better efficiency and productivity. ↩

Understanding consumables is key to maintaining efficiency and quality in plasma cutting. ↩

Explore the implications of the heat-affected zone on metal properties after cutting. ↩

Safety is paramount; explore essential precautions for using plasma cutting equipment. ↩

Understand the need for proper ventilation to ensure a safe working environment during plasma cutting. ↩

Avoid costly mistakes by learning which materials are unsuitable for plasma cutting. ↩