Are your clients asking tough questions about plasma cutting technology1? Many distributors struggle to offer detailed answers. I found that gaining deep knowledge truly solves this problem.

Understanding plasma cutting is critical because it empowers distributors like us to confidently address client inquiries, differentiate from competitors effectively, and recommend optimal solutions, directly impacting customer trust and boosting sales.

My own journey into this complex world showed me just how much a little well-placed knowledge can unlock. I realized that truly serving our clients well means giving them thoughtful answers, not just packaging products. So, join me as we explore what makes this technology tick and why it matters directly for our sales efforts and our clients’ success.

What Exactly Is Plasma, And How Does It Cut So Precisely?

Have you ever truly wondered what plasma actually is? It is not just fire, but a fourth state of matter. Understanding this crucial concept will truly set us apart.

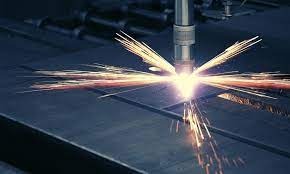

Plasma is an ionized gas2, reaching extreme temperatures (up to 22,000°C) which melts metal instantly. A highly concentrated arc then precisely blows away molten material, making exceptionally clean and accurate cuts possible.

I remember my early days, grappling with this concept. It felt so foreign at first. My mentor explained it simply: imagine gas heated so intensely that its electrons break freely from atoms. This extreme energy creates a super-conductive, super-hot stream. When we apply this incredibly powerful stream to metal, it instantly turns the solid material into liquid, then rapidly into vapor. The high-velocity gas3 quickly removes the molten material from the cut zone.

This unique process gives ARCTHERM equipment4 its legendary "Precision in Power." We do not just create heat; we control this incredible intensity with advanced systems that precisely manage current, voltage, and gas flow5. This meticulous control is what consistently delivers unparalleled cutting precision6. It means less rework for our customers and higher quality end products for their clients. It truly is fascinating how we harness fundamental physics to achieve such practical benefits.

| Property | Plasma Arc (Core) | Sun's Surface (Approx.) |

|---|---|---|

| Temperature | Up to 22,000°C (40,000°F) | 5,500°C (10,000°F) |

| State of Matter | Ionized Gas ("Fourth State") | Plasma/Gas |

| Function | Melting & Cutting Metal | Nuclear Fusion/Heat |

| Conductivity | Highly Conductive | Conductive |

How Does Plasma Cutting Compare to Other Metal Cutting Methods?

Clients often ask: "Why choose plasma over laser or oxyfuel?" This is a truly crucial question. Knowing the detailed answer definitively boosts your credibility.

Plasma cutting excels in speed and versatility for conductive metals, offering a balance of precision and cost-effectiveness7. It is often faster than oxyfuel and more economical than laser or waterjet for many applications.

My mentor always stressed: you must know your tools inside and out. When a customer hesitates between plasma and another cutting method, knowing the specific differences often solves their problem directly. For example, oxyfuel is good for very thick carbon steel, but it is slow, often messy, and limited to ferrous metals. Laser cutting offers superb precision for thin sheets and intricate designs, but the equipment cost is very high, and operating expenses can be significant. Waterjet cutting can cut almost any material, including non-metals, and leaves no heat-affected zone, but it is typically very slow and involves abrasive material costs.

Plasma, on the other hand, hits a powerful sweet spot. It cuts fast, handles a wide range of conductive metals (including stainless steel and aluminum), and offers a compelling balance of affordability and capability. This makes it a primary choice for a vast number of fabrication shops8 and manufacturers. We tell our ARCTHERM sales team this often. It truly helps them build trust and solve real-world challenges for their own clients, providing clear, actionable advice.

| Feature | Plasma Cutting | Oxyfuel Cutting | Laser Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Materials | All Conductive Metals | Carbon Steel Only | Wide range (incl. non-metals) | Virtually all materials |

| Speed | High (medium thick focus) | Moderate (slow for thin) | Very High (Thin sheets) | Slow |

| Precision | Good (medium clean kerf) | Moderate (rougher cut) | Very High (fine kerf) | Very High (no heat affected) |

| Max Thickness | Moderate to Thick (>150mm) | Very Thick (>300mm) | Thin to Medium (>20mm) | Very Thick (>300mm) |

| Cost | Medium | Low | High | High |

| Heat Affected Zone | Moderate | Large | Minimal | None |

What Makes ARCTHERM's Plasma Solutions Stand Out in the Market?

You need to clearly differentiate yourself in a crowded market. How can ARCTHERM's solutions truly help you stand out? It comes down to precision and proven heritage.

ARCTHERM stands out with 15 years of precision manufacturing, leveraging Japanese-imported core components for superior reliability and offering comprehensive solutions with global support, embodying true "Precision in Power."

The company founder often tells me about the earliest days. He understood the critical importance of quality. He chose to invest heavily in Japanese core components because he simply understood their inherent "Precision in Power." This uncompromising legacy lives on in every single ARCTHERM machine we produce today. We do not merely assemble parts; we meticulously craft each system. This approach means our handheld units are rugged and reliable for demanding on-site work, our CNC systems9 are ultra-precise for high-volume automated production, and our robotic solutions10 handle the most complex 3D shapes with ease. My daily learning involves seeing directly how this commitment translates into tangible benefits for our clients—things like faster cuts, consistently cleaner edges, and significantly less machine downtime.

This is why our clients consistently see ARCTHERM as a valuable partner, not just a mere supplier. We help them solve their production problems11, and that directly helps you, Marco, stand out as an indispensable resource to your own clients. Our extensive experience gives us unique insights, which we continuously refine into smarter, more efficient solutions for the entire industry.

| ARCTHERM Advantage | Description | Benefit for Distributors & Clients |

|---|---|---|

| Japanese Core Components | Guaranteed precision and exceptional durability. | Superior reliability, reduced maintenance, consistent results. |

| 15 Years Experience | Deep industry knowledge, proven solutions. | Trusted guidance, innovative products, problem-solving expertise. |

| Comprehensive Product Line | Handheld, CNC, Robotic, Software, Consumables. | One-stop solution, caters to diverse needs, scalable. |

| Global Support Network | Timely assistance and dedicated localized service. | Reduced downtime, access to expert knowledge, peace of mind. |

| "Precision in Power" | Consistent, high-quality cutting performance. | High-quality output, maximized material usage, cost savings. |

How Do ARCTHERM Consumables Impact Cutting Quality and Your Bottom Line?

Many people overlook consumables12, but they are truly vital. Are your clients using the right ones? This directly affects their profits.

ARCTHERM's high-quality consumables like electrodes and nozzles13 are crucial components. They ensure optimal arc performance, extend operational lifespan reliably, deliver superior cut quality, and ultimately reduce long-term operating costs for your valued clients.

This is genuinely where the experienced sales veterans truly distinguish themselves. They understand that opting for cheap, low-quality consumables is a complete false economy. I have personally seen this play out many times. Sub-par electrodes or nozzles wear out incredibly fast, cause noticeably poor cuts, and almost force frequent, disruptive replacements. This translates directly into more unproductive downtime and significant material waste14 for the client.

With ARCTHERM's consumables, which are meticulously produced with the same exacting Japanese precision as our machines, you are not just selling a part. You are selling unwavering durability and consistently reliable performance. Our hafnium-copper electrodes and precisely manufactured nozzles ensure a stable, focused arc and a consistently clean cut. This setup actively prolongs component life and keeps machines running smoothly with fewer interruptions. This directly helps Marco's clients save substantial money over time, making you an absolutely invaluable resource to them. It is an extremely powerful and clear message for any industrial distributor aiming for long-term client relationships.

| Consumable Type | ARCTHERM's Quality Benefit | Impact on Cutting & Cost |

|---|---|---|

| Electrodes | Hafnium-Copper, extended lifespan | Stable arc, longer run times, less material waste14. |

| Nozzles | Precision-machined orifice | Concentrated arc, clean cuts15, reduced rework. |

| Shield Caps | High-temperature, wear-resistant | Protect torch, extend consumable life, lower overall cost. |

| Complete Kits | Matched performance, guaranteed fit | Optimal system performance, simplified selection. |

Conclusion

Mastering plasma technology truly empowers industrial distributors like us. ARCTHERM consistently provides the cutting precision6, comprehensive solutions, and deep knowledge you need. This helps our clients achieve superior production results reliably.

Explore advancements in plasma cutting technology to stay ahead in the industry and better serve your clients. ↩

Learn about ionized gas to grasp its significance in plasma cutting processes. ↩

Understanding high-velocity gas can enhance your knowledge of cutting processes. ↩

Find out what sets ARCTHERM equipment apart and how it can benefit your operations. ↩

Understanding these factors can help optimize plasma cutting operations. ↩

Discover how cutting precision affects quality and efficiency in manufacturing. ↩

Explore the cost-effectiveness of plasma cutting to make informed recommendations. ↩

Discover best practices to enhance efficiency and quality in fabrication shops. ↩

Explore how CNC systems can enhance precision and productivity in cutting. ↩

Discover the benefits of robotic solutions for enhancing cutting efficiency. ↩

Explore how effective plasma cutting solutions can address common production challenges. ↩

Explore how consumables impact cutting quality and operational costs. ↩

Learn how to choose the right consumables for optimal cutting performance. ↩

Learn strategies to minimize material waste and improve profitability. ↩

Discover techniques for achieving clean cuts to improve client satisfaction. ↩